Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

AH slurry pump

- 产品描述

-

Purpose and function

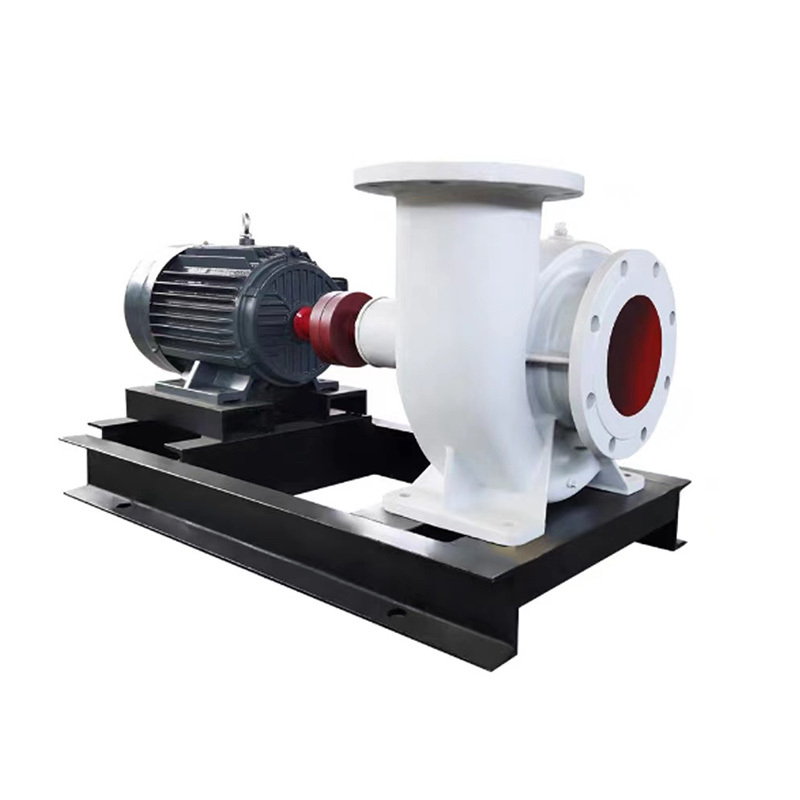

M, AH, HH type for cantilever, horizontal centrifugal slurry pump, suitable for metallurgy, mining, coal, electric power, building materials and other industrial sectors to transport strong abrasion, high concentration of slurry. This type of pump can also be used in multiple stages in series.

The pump body of M and AH type pump has replaceable wear-resistant metal lining or rubber lining, and the impeller is made of metal or rubber material. The pump body lining and impeller of HH type pump are only made of wear-resistant metal. The shaft seal of M, AH, HH type pump can adopt packing seal or centrifugal seal. The outlet position of the pump can be changed to 45 intervals according to the needs, and eight different angles of rotation can be installed and used.

Model meaning

For example:

10/8ST--AH (or M,HH)

10-Diameter of pump suction port (inch)

8-Diameter of pump outlet (inch)

HH -- high-lift slurry pump

M, AH -- slurry pump

ST -- Bracket typeSelection profile

Refer to the pump performance curve, and the selected flow range should be

M, AH type pump

For high concentration, strong abrasive slurry flow range of 40 ~ 80%

Medium concentration, strong abrasive slurry flow range of 40~100%

For low concentration, strong abrasive slurry flow range of 40~120

Hh type pump:

Medium concentration, medium abrasive slurry flow range of 40 ~ 80%

For low concentration, low abrasive slag slurry flow range of 40~100%

(The maximum efficiency point at a 1 speed corresponds to a flow rate of 100%)Structure Diagram

1. Sheath

2. Pump body

3. Rear guard plate

4. Pump cover

5. Front guard plate

6. Impeller

7. Stuffing box

8. Shaft sleeve

9. Shaft

10. Bearing body

11. Bracket

12. Oil cup

13. Open packing gland

14. Auxiliary impeller

15. Pressure relief cover

16. Filler

17, water seal ring

18. Lip seal ringProduct Parameters

Type A B C D U E F G H J K L M N V T 1331/1B-AH 583 295 248 197 28 79 206 181 98 171 46 - 143 254 181 38 1441/1C-HH 759 406 311 254 42 121 306 270 194 254 - 11 175 356 252 48 2/132/31B-AH 592 295 248 197 28 79 217 205 114 184 33 - 143 254 184 38 3/23/2C-AH 768 406 311 254 42 121 281 238 138 210 71 - 175 356 233 48 3/23/2D-HH 986 492 364 330 65 164 389 384 254 368 - 51 213 432 298 64 4/34/3C-AH 843 406 311 254 42 121 354 292 149 262 24 - 175 356 270 48 4/34/3D-AH 943 492 364 330 65 164 353 292 149 262 100 - 213 432 279 64 4/34/3E-HH 1240 622 448 457 80 222 492 392 330 432 - - 257 546 381 76 6/46/4D-AH 1021 492 364 330 65 164 421 406 229 338 11 - 213 432 318 64 6/46/4E-AH 1178 622 448 457 80 222 433 406 229 338 138 - 257 546 351 76 6/46/4S-HH 1668 920 780 450 120 280 596 616 413 546 - 134 640 760 353 90 8/68/6E-AH 1302 622 448 457 80 222 557 551 318 460 - 62 257 546 402 76 8/68/6R-AH 1360 680 590 350 85 215 - 511 318 460 - 170 490 560 312 70 8/68/6T-HH 2275 1150 1040 650 150 350 852 835 584 813 - 160 880 900 538 125 10/810/8E-M 1337 622 448 457 80 222 584 613 381 470 - 83 257 546 403 76 10/810/8R-M 1395 680 590 350 85 215 - 613 381 470 - 190 490 560 314 70 10/810/8ST-AH 1748 1150 780 650 120 280 692 673 419 635 27 - 620 900 439 125 12/1012/10ST-AH 1816 1150 780 650 120 280 762 755 464 674 - 65 620 900 461 125 14/1214/12ST-AH 1873 1150 780 650 120 280 812 937 629 832 - 224 620 900 486 125 16/1416/14TU-AH 2320 1460 1050 900 150 350 953 1048 660 889 - 84 860 1200 597 150 20/1820/18TU-AH 2475 1460 1050 900 150 350 1100 1420 940 1230 - 420 860 1200 615 150 6S-H 1700 920 780 450 120 280 622 625 415 615 - 135 640 760 382 90

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How long is the cycle of customized products?

A

Q

Do you support product customization? What aspects can be customized?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How long is the cycle of customized products?

A

The customization cycle will vary depending on the complexity of the product and the volume of the order. In general, it takes about 1 week from requirement confirmation to sample delivery, and mass production is completed within 3 weeks after sample confirmation. We will give a more accurate estimated time when communicating with you, and feedback the progress to you in the production process.

Q

Do you support product customization? What aspects can be customized?

A

Yes, we have strong customization capabilities. The pump body material (such as wear-resistant alloy, anti-corrosion rubber, special steel, etc.), caliber size, export direction, overall size, length under liquid, etc. can be customized according to your needs. At the same time, you can also choose electric motors or diesel engines and other power equipment.