Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

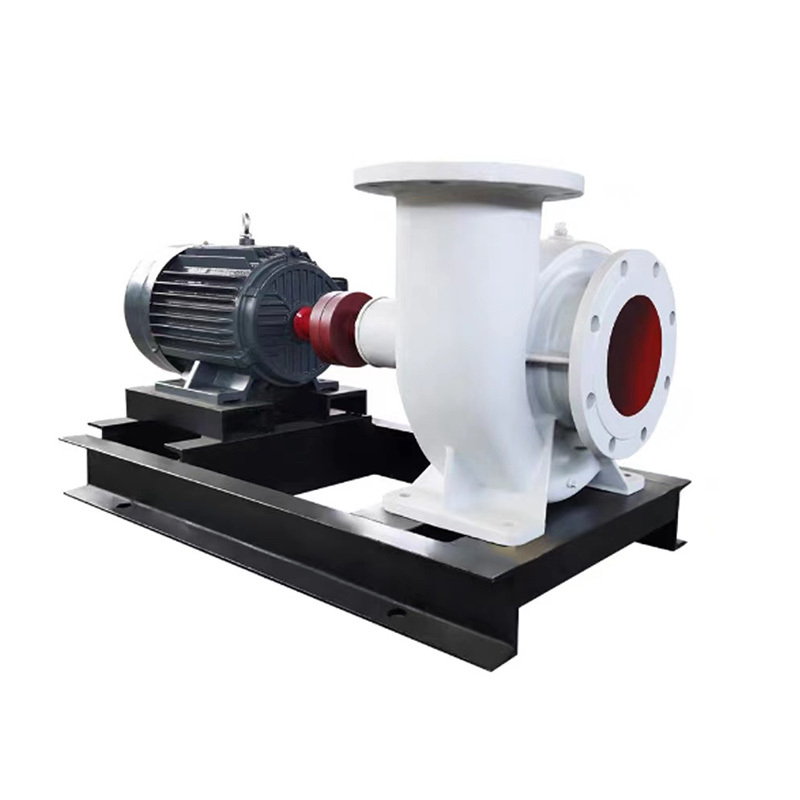

YZ multi-head slurry pump

- 产品描述

-

Summary

YZ YTl type liquid slurry pump is verticalsingle stage single suction cantilevercentrifugal pump impellerstructure,semiopenimpeller, a stirring blade extends in impellersuction side.

this series pump is mainly used for desul-furization environmental protection, munici-pal engineering,thermalpowerplant,gascoking plants,oil refineries,steel mills,mining,paper making,cement factory,foodfaetory, printing and dyeing industry, heavyoil,diesel,suction liquidwaste etchingsolution,slurry,mortar,sand and city sewagechannel flow sludge containing coal, ash, and.Can also be used as chemical,pharmaceuticalfluid suctionand other industries withsedimentslurrymaterial andcorrosiveliquids.YZ type overcurrent pieces of material Gr26,Gr27,304,316

YTL type overcurrent and other pieces ofmaterial Gr30A,A49,etc.

pump type and meaning:example:80YTL80-20A80YZ80-20A

DesulfurizationpumpYZ-submerged underliquid slurry pump YTL

80-pump outlet diameter(m)

80-pump design point flow(m3/h))

20-pump design point lift(m)cutting

A- impeller through

the first pump:pump through theel asticdrive. See from the direction of the original motivation for the clockwise direction of rotation.

The description of the structure

YZ YTL type pump is a single-stage, single suc-tion cantilever structure, the bearing, bearing seat, theconnecting pipe hydraulic components connectedpump, liquid from the discharge pipe part discharge,pump impeller is a semi open type leaf, mixing bladesare arranged in the impeller blade inlet extends, thepump is mainty characterized in the liquid part of thepump shaft, have enough stiffness, impeller, pumpshell between the non bearing, without the use of shaftseal, can be transmitted with high concentration solidgranules medium. Liquid pump inserted length be.tween 800-2500, if you need to be equipped with suc-tion pipes, liquid pump seal used to run insert liquid, noseal,transmission by the vertical electric motor in-stalled in the bearing and the bearing seat, connectedby coupling with the pump.

Structural Drawing of YZ/YTl Slurry Pumps

1、 Suction cover

2、lmpeller

3、The pump body

4、The pump cover

5、 Liquid outlet elbow

6、 The liquid outlet pipe

7、 The connecting tube

8、 The supporting seat

9、Bearing

10、Shaft

11、The bearing seat

12、Bearing

13、Bearing components14、 Motor bearing

15、Electric machinery

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How long is the cycle of customized products?

A

Q

Do you support product customization? What aspects can be customized?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How long is the cycle of customized products?

A

The customization cycle will vary depending on the complexity of the product and the volume of the order. In general, it takes about 1 week from requirement confirmation to sample delivery, and mass production is completed within 3 weeks after sample confirmation. We will give a more accurate estimated time when communicating with you, and feedback the progress to you in the production process.

Q

Do you support product customization? What aspects can be customized?

A

Yes, we have strong customization capabilities. The pump body material (such as wear-resistant alloy, anti-corrosion rubber, special steel, etc.), caliber size, export direction, overall size, length under liquid, etc. can be customized according to your needs. At the same time, you can also choose electric motors or diesel engines and other power equipment.