Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

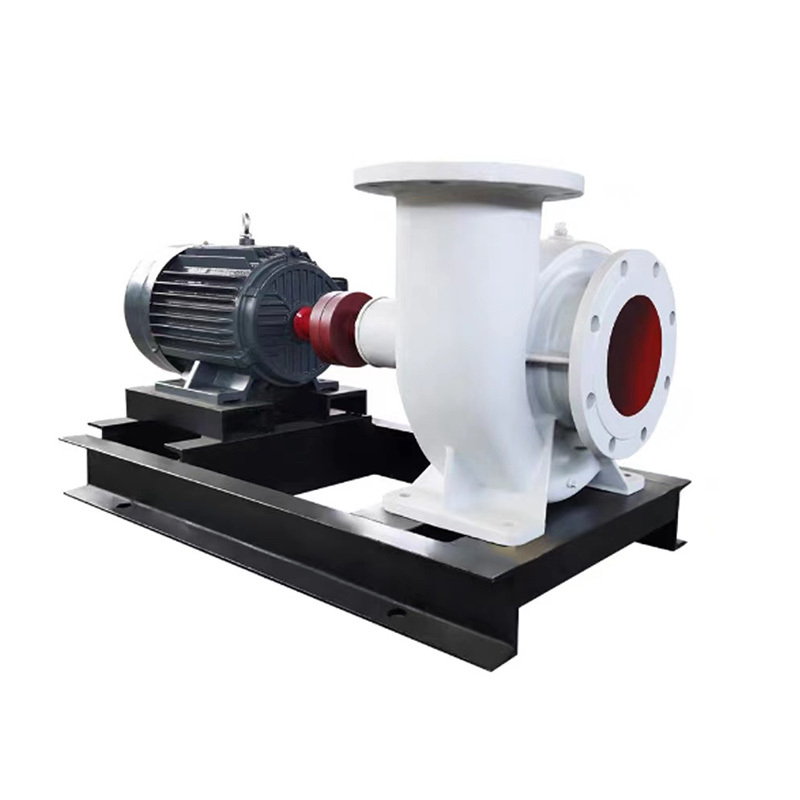

DT single shell slurry pump

- 产品描述

-

The purpose and scope of application of the pump

The DT series desulfurization pumps developed by our factory are divided into two structures: horizontal (DT) and vertical (TL). For axial suction, single suction, cantilever centrifugal structure. This series of pumps comprehensively applies the advantages of similar products at home and abroad and innovates in hydraulic design, structural design, and materials used for castings. It has the characteristics of high efficiency, energy saving, corrosion and wear resistance, low vibration, low noise, reliable operation, long service life, and easy maintenance. The comprehensive performance of the pump is at the leading level in China. It can be widely used in desulfurization systems for industries such as thermal power plants, aluminum refineries, and oil refineries to transport limestone or gypsum slurry. The allowable chloride ion concentration in the slurry is 60000ppm, and the pH value of the slurry is allowed to be between 2.5-13.

Types and structural characteristics of pumps

There are two main types of DT series desulfurization pumps. One is the DT type, which is a horizontal, axial suction, single-stage, single suction, centrifugal desulfurization pump; The other type is TL type, which is a vertical, axial suction, single-stage, single suction, centrifugal desulfurization pump.

1. Structural characteristics and models of DT type horizontal desulfurization pump

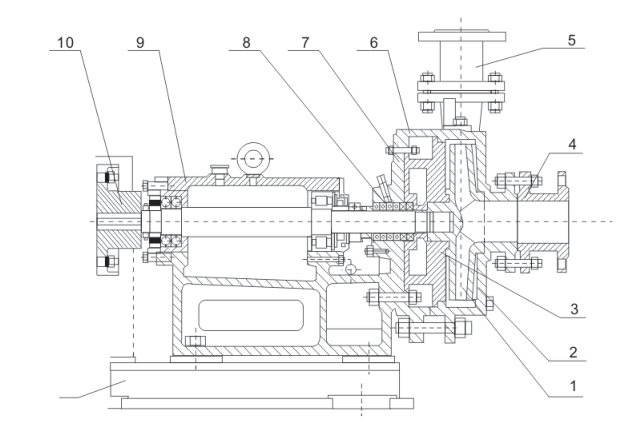

(1) The structural characteristics of DT type horizontal desulfurization pump include impeller, volute, rear guard plate, packing box, liner plate and shaft seal device. The pump head of DT type horizontal desulfurization pump is a single-layer shell structure. The overcurrent components are made of corrosion-resistant and damage resistant cast alloys (including blade snail shell, rear guard plate, and liner plate). The impeller and shaft are connected by threads.

The bracket is lubricated with thin oil. It mainly consists of parts such as bracket body, bracket cover, shaft, bearing box, bearing, bearing cover, sleeve, nut, oil seal, water blocking plate, etc. The detailed structure of DT type desulfurization pump is shown in Figure 1.There are two main types of DT series desulfurization pumps. One is the DT type, which is a horizontal, axial suction, single-stage, single suction, centrifugal desulfurization pump; The other type is TL type, which is a vertical, axial suction, single-stage, single suction, centrifugal desulfurization pump.

Structural diagram

1. Impeller

2. Spiral shell

3. Rear guard plate

4. Entrance short pipe

5. Export short pipe

6. Packing box

7. Lining board

8. Mechanical seal

9. Bracket

10. Coupling

11. Base

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How long is the cycle of customized products?

A

Q

Do you support product customization? What aspects can be customized?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How long is the cycle of customized products?

A

The customization cycle will vary depending on the complexity of the product and the volume of the order. In general, it takes about 1 week from requirement confirmation to sample delivery, and mass production is completed within 3 weeks after sample confirmation. We will give a more accurate estimated time when communicating with you, and feedback the progress to you in the production process.

Q

Do you support product customization? What aspects can be customized?

A

Yes, we have strong customization capabilities. The pump body material (such as wear-resistant alloy, anti-corrosion rubber, special steel, etc.), caliber size, export direction, overall size, length under liquid, etc. can be customized according to your needs. At the same time, you can also choose electric motors or diesel engines and other power equipment.