Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

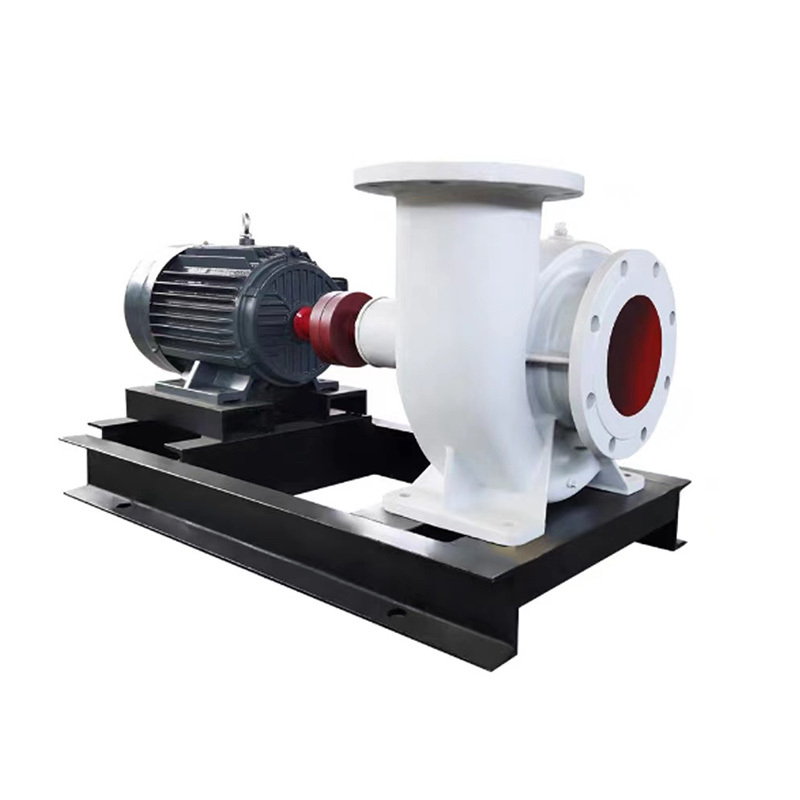

S SH double suction pump

- 产品描述

-

Summary

S. SH type pump is a single-stage, double suction, pump shell split centrifugal pump used for sucking and delivering clean water and liquids with physical and chemical properties similar to water.

When the head of this type of pump is between 9 meters and 140 meters, the flow rate is between 126 meters/hour and 12500 meters/hour, and the maximum temperature of the liquid should not exceed 80 ℃. It is suitable for factories, mines, urban water supply, power stations, large-scale water conservancy projects, farmland irrigation and drainage, etc. The 48SH-22 large pump can also be used as a circulating pump for thermal power plants.The meaning of pump model: such as 10SH-13A

The diameter of the suction port is divided by 25 (i.e. the diameter of the suction port of the pump is 250 millimeters)

S. SH --Double suction single-stage horizontal centrifugal clean water pump

13--Specific speed divided by 10 (i.e. the specific speed of the pump is 130)

A--indicates that the pump has replaced the impeller with a different outer diameterStructural description

S. The suction and discharge ports of the SH type pump are both located below the axis of the pump, in a horizontal direction and perpendicular to the axis. The pump cover of the pump is fixed to the pump body with double headed bolts and conical positioning screws, making it easy to open and inspect all parts inside the pump without disassembling the inlet and outlet pipelines

As a result, the maintenance of the electric motor is extremely convenient. From the perspective of the transmission direction, the SH type water pump rotates counterclockwise; The S-shaped water pumps all rotate clockwise

Turn;

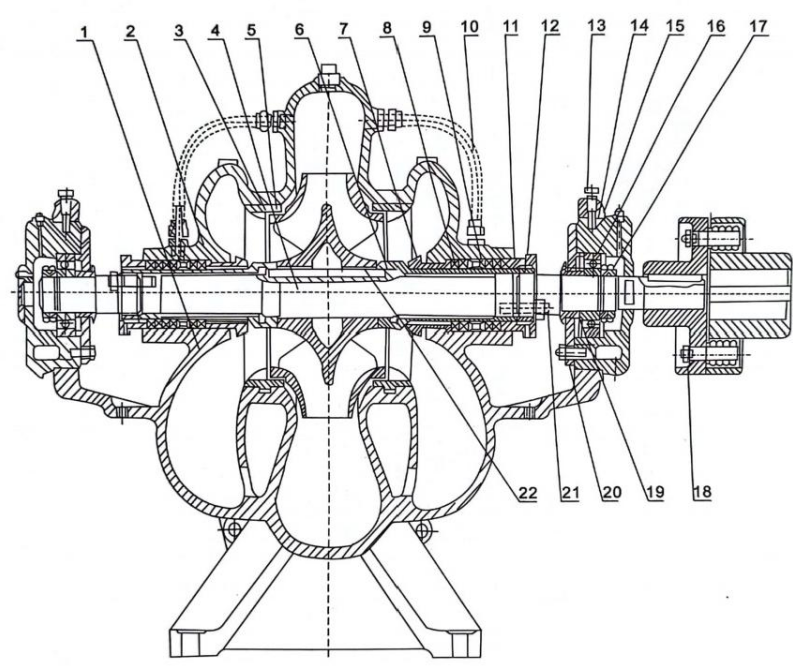

S. The main components of SH type pump include: pump body (1), pump cover (2), impeller (3), shaft (4), double suction sealing ring (5), shaft sleeve (6), and bearing body (14).The pump body (1) is made of cast iron. The working chamber that forms the impeller with the pump cover has pipe screw holes for installing vacuum and pressure gauges on the flanges of the inlet and outlet channels. The lowest disposal point for the neck of the pipe is a screw hole for draining water.

The pump cover (2) is made of cast iron. There are screw holes on the upper part for installing water seal pipes and vent pipes, as well as hooks for lifting the pump cover.

The impeller (3) is made of cast iron and has a symmetrical shape with twisted blades between the two walls. Liquid enters the impeller from both sides and undergoes static balance testing during manufacturing.

Shaft (4) is made of high-quality carbon steel. The center of the shaft is the impeller, which is fixed with keys, shaft sleeves, and shaft sleeve nuts on both sides. The right end of the shaft is equipped with a coupling, which is directly connected to the motor. Belt transmission is not allowed at the coupling end. If belt transmission is required, a separate support bracket must be installed

Hold the pulley.

Double suction sealing ring (5) is made of cast iron to prevent high-pressure water from leaking back into the inlet part of the water pump. A protruding semi-circular ring is made on the double suction sealing ring and embedded in the pump body to fix it. It is a vulnerable part and can be replaced with spare parts after wear.

The shaft sleeve (6) is made of cast iron and is used to fix the position of the impeller and protect the wear of the shaft inside the packing chamber. It is a vulnerable part and can be replaced with spare parts after wear.

S. The SH type pump has two supports and uses a single row radial ball bearing. The bearing part A, located near one end of the coupling in the bearing body (14), and the other end, referred to as bearing part B, are lubricated with grease. Due to the complete symmetry of the impeller, theoretically, the water pump does not generate axial force. However, in manufacturing, it is difficult to achieve exactly the same gap between the water flow passing parts and the sealing ring on both sides of the water pump. Therefore, the water pump may generate axial force, which is borne by the single row radial ball bearing in part B of the bearing.

The packing plays a sealing role, preventing air from entering the pump and the leakage of large amounts of liquid. The packing seal consists of a composite packing chamber, packing cover, packing ring, packing sleeve, and packing on the pump body and pump cover. A small amount of high-pressure water inside the pump cover flows into the packing chamber through the external water seal pipe (or internal water tank) and packing ring, serving as a water seal.

The tightness of the packing must be appropriate, neither too tight nor too loose, based on the liquid's ability to leak out drop by drop. If the packing is too tight, the bearing is prone to heating and consumes power. If the packing is too loose and the liquid leaks, it will reduce the efficiency of the water pump.Structural diagram

1. Pump body

2. Pump cover

3. Impeller

4 . axle

5. Double suction sealing ring

6. Shaft sleeve

7. Packing bag

8. Filler

9. Packing ring

10. Water seal pipe

11. Packing gland

12. Shaft sleeve nut

13. Fixing screws

14. Bearing body

15. Bearing body cover

16. Single row radial ball bearing 17 Nut

18. Coupling components

19. Bearing sleeve

20. Bearing end cap

21 . key

22. Double headed bolt

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.