Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

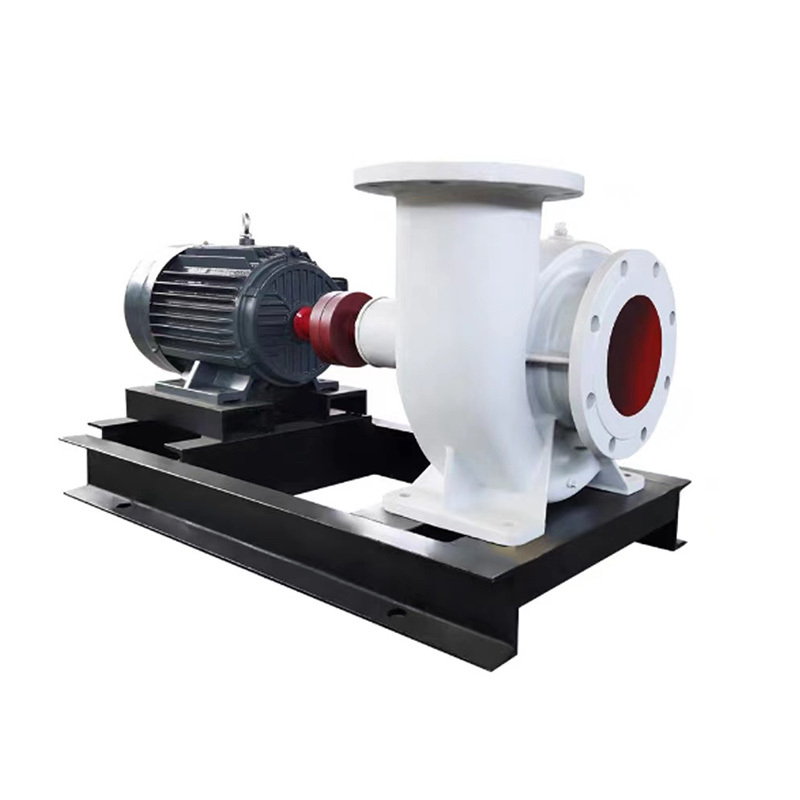

ZJW Filter Press Feeding Pump

- 产品描述

-

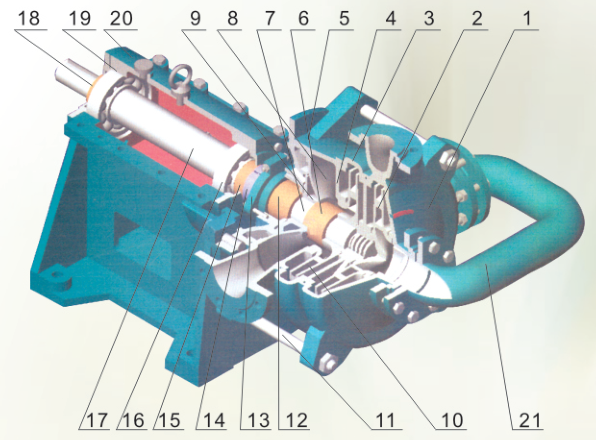

Sketch

ZJE-Ⅱ specialized pump is a type of impurity pump with special performance. In recent years, it has been referred to as the "specialized feed pump for filter presses" by industry insiders. The pump sucks in slurry from the rear side, with simple packing sealing and no leakage. More importantly, its flow and head curves are very steep, making it very suitable for some special working conditions.

Feature

1. Advanced and innovative hydraulic and structural design, high efficiency, corrosion resistance, and stable and reliable operation;

2. The initial feed flow rate is high and the pressure is low;

3. The later pressing flow is small and the pressure is high;

4. The shaft seal is simple and reliable, without water injection or mechanical sealing, and has no leakage;

5. Filter feeding does not require variable frequency speed regulation, resulting in high conveying concentration.Select

The main technical parameters listed in this document are the data of the pump at 1480r/min. For working conditions that require low pressure, the impeller can be cut appropriately or the pump speed can be reduced to solve the problem. We can also choose the ZJ series slurry pump produced by our factory. The mechanical seal of the ZJ pump is "leak free" like the ZJE-1 pump. This information only provides a few basic dimensions for direct drive. Due to terrain limitations or changes in pump speed, the basic dimensions of the belt drive will be designed separately based on specific data provided on site. Belt transmission methods generally include tailstock, parallel, and back support transmission.

This pump is a pressure inlet suction pump with a small suction stroke. It is recommended that the feed liquid level be higher than the center of the pump. The diameter of the inlet and outlet pipelines is generally the same as or slightly larger than the inlet and outlet diameters of the pump, so the liquid concentration is mostly high. Therefore, the inlet pipeline of the pump should not be too long to avoid affecting the suction.Main technical parameters of direct drive

Model Speed (r/min) Flow rate (m ³/h) Head (m) Maximum shaft power (kW) Reference motor Power (kW) 50ZJE-II 1480 30 76.0 15 Y180L-4 22 40 72.2 50 66.1 58 56.0 70 43.5 Y200L-4 30 65ZJE-II 1480 41.4 76.0 22.3 Y225S-4 30 55.2 72.2 69.0 66.1 80.0 56.0 100 43.5 Y200L-4 37 80ZJE-II 1480 60.0 76.0 32 Y225S-4 37 80.0 72.2 100 66.1 115 56.0 135 43.5 Y225M-4 45 100ZJE-II 1480 85.0 73.3 49 Y225M-4 45 113 69.0 150 62.5 169 51.2 175 44.0 Y250M-4 55 125ZJE-II 1480 105 73.5 62.5 Y250M-4 55 140 71.6 186 68.6 245 61.9 265 48.5 125ZJE-II 1480 119 80.0 78.2 Y280S-4 75 159 78.0 211 74.8 279 67.5 305 52.9 125ZJE-II 1480 87.0 91.8 64.7 Y280S-4 75 116 89.1 154 85.7 203 77.3 215 60.6 Structural diagram

1. Secondary snail shell

2. Secondary impeller

3. First level snail shell

4. Protective board

5. Feeding room

6. Positioning set

7. Auxiliary impeller

8. Auxiliary impeller cover plate

9. Decompression body

10. First stage impeller

11. Pull the bar

12. Shaft sleeve

13. Material cover

14. Disassemble the ring

15. Water blocking plate

16. Bearing

17. Axis

18. Bearing sleeve

19. Bearing gland

20. Bracket

21. Bend pipe

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.