Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

MDP self-balancing multistage pump

- 产品描述

-

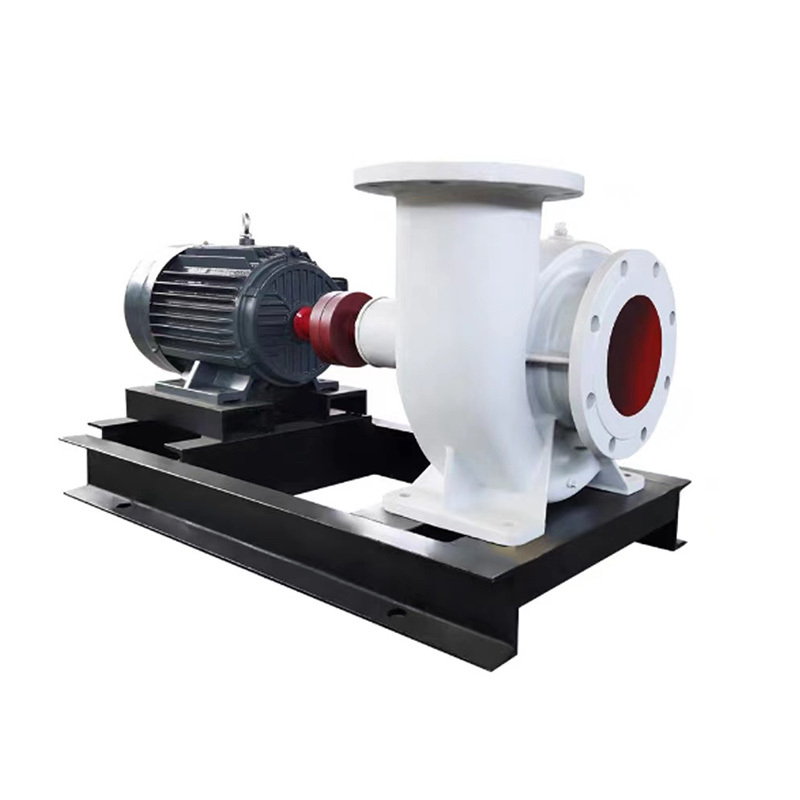

Overview

This series of pumps is a horizontal single suction multi-stage segmented centrifugal pump with 6 national patents. It has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long service life, and easy installation and maintenance.

It can be used to transport media containing solid particles (particle diameter less than one fourth of the impeller channel), and can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump (or the material of the pump's flow passage), sealing form, and adding a cooling system.

The operating temperature of the ZD, ZDG, ZDF, ZDY, ZMD series horizontal multi-stage centrifugal pumps is -60 ℃~400 ℃. Various materials are available for users to choose from, including HT200, QT600, JM3, 28 # alloy, 304, 304L, 316L, 317L, 9041L, CD4, Hastelloy C, Hastelloy B, etc.

Our company has passed the IS09001:2000 quality system certification, and our product design, production, and service have strict and standardized control systems, ensuring sufficient product quality assurance.Parameter range (design point)

Flow rate: 7.5~864m 3/h

Head: 46~2070m

Model Description

ZD (ZDG, ZDF, ZDY, ZMD) 46-30x4

ZD - represents a self balancing multi-stage clear water centrifugal pump

ZDG - stands for self balancing multi-stage wear-resistant centrifugal pump

ZDF - stands for self balancing multi-stage corrosion-resistant centrifugal pump

ZMD - stands for multi-stage wear-resistant and corrosion-resistant centrifugal pump for self balancing coal mines

46- indicates a design point flow rate of 46m 3/h

30- indicates a single-stage lift of 30m at the design point

4--Indicating a level of 4Structural characteristics

1. The impellers of ZD, ZDG, ZDF, ZDY, and ZMD horizontal multi-stage centrifugal pumps are symmetrically arranged, which can basically eliminate axial forces. The residual axial forces are borne by a pair of back-to-back angular contact ball bearings. Due to the absence of a balancing device, which includes both disc friction loss and reflux loss, the pump efficiency is increased by 5-14% compared to multi-stage pumps of the same category. At the same time, it completely solves various pump failures caused by the failure of the balancing device, greatly extending the service life of the pump.

2. Adopting high-end sealing: Traditional multi-stage pumps used in mining use packing sealing, which has the advantage of being resistant to particle impurities, but there are leakage problems during use. Mechanical seals have no leakage, but their service life is very short when used in media with particle impurities. The new multi-stage pump for mining produced by our company adopts a high-end seal, which combines the advantages of packing seal and mechanical seal. It can be used for a long time in media with particle impurities without leakage. This seal is a new patented high-end seal developed by our company that is resistant to particle impurities

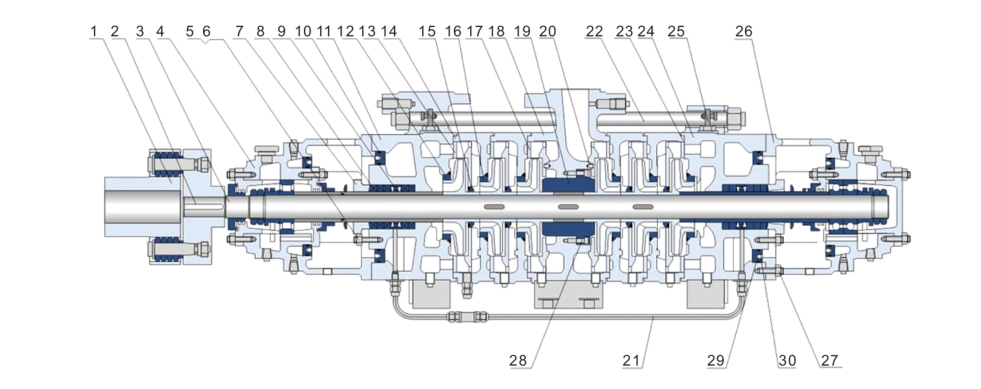

Sealed. 3. The bearing seat never gets water: This technology is a newly developed patented technology by our company, which ensures that no liquid enters the bearing seat during use and at rest, further extending the service life of the bearing and reducing maintenance costs for users.Structural diagram

1、Coupling Assembly

2、Key

3、Rotating Assembly

4、Bearing Housing A Assembly

5、 Stud

6、Nut

7、Packing Gland

8、 Packin

9、Lantern Ring

10、Cooling chamber Cover

11、Suction Casing

12、Wear ring

13、 Diffuser

14、Stage Casing

15、Inter-stage Bushing

16、Wear ring

17、Discharge Diffuser

18、Discharge Casing

19、Orifice Sleeve

20、 Dowel Pin

21、Seal Flush Pipe Assembly

22、Tie bolt

23、Gasket

24、2nd Suction Casing

25、Air Release Valve

26、Bearing Housing B Assembly

27、 Stud &Nut

28、Hexagon Socket Head Cap Screw

29、 O-ring

30、O-ring

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.