Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

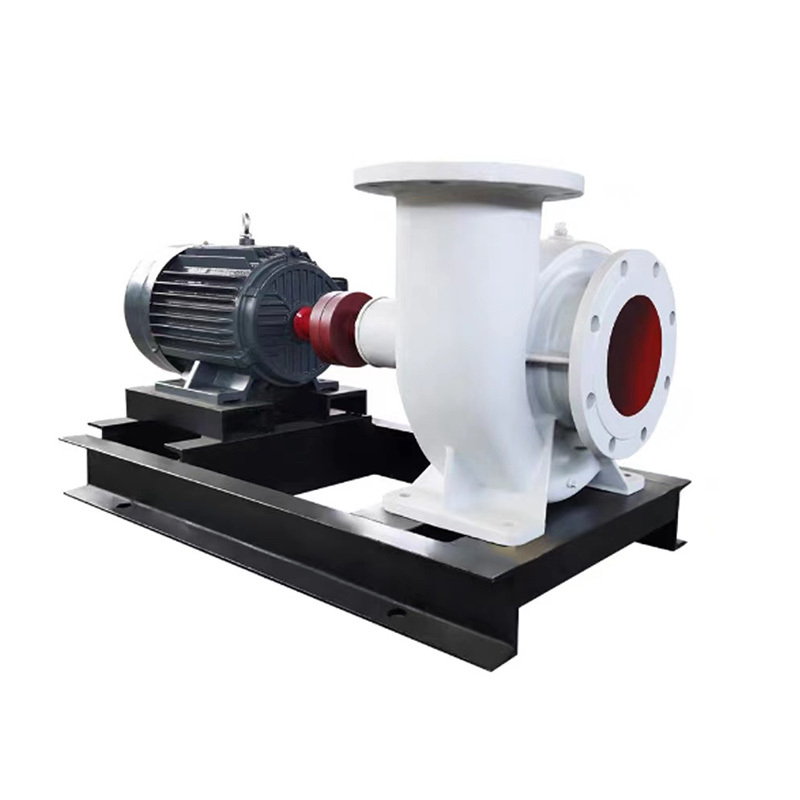

HW mixed flow pump

- 产品描述

-

Overview

1. Purpose:

The HW type pump is a horizontal, single-stage, single suction, volute mixed flow pump. Suitable for transporting clean water or other liquids with physical or chemical properties similar to water. The temperature of the transported liquid should not exceed 50 ℃. Widely used in various occasions such as agricultural irrigation, industrial and urban water supply and drainage.

The performance range of HW pump: flow rate of 90-9000m '/h, head of 3.5-22m.

2. Characteristics:

Simple structure, reliable use, convenient decoration, high efficiency, small size, and light weight.

3. Transmission mode:

There are direct transmission and variable speed transmission. The commonly used power engines are electric motors and diesel engines. When ordering, the model of the power machine (power, speed) should be clearly specified in order to determine the specifications of the coupling or pulley.

4. Water pump direction:

When looking at the inlet of the water pump (650HW-5, -7, -10 pumps rotate clockwise), the impeller generally rotates counterclockwise

5. Model Description: Taking 100HW-8S as an ExampleTaking 100HW-8S as an example

100- Pump inlet and outlet diameter mm

HW - Horizontal Vortex Shell Mixed Flow Pump

8-- Design head

S - Variant codeStructure and Function

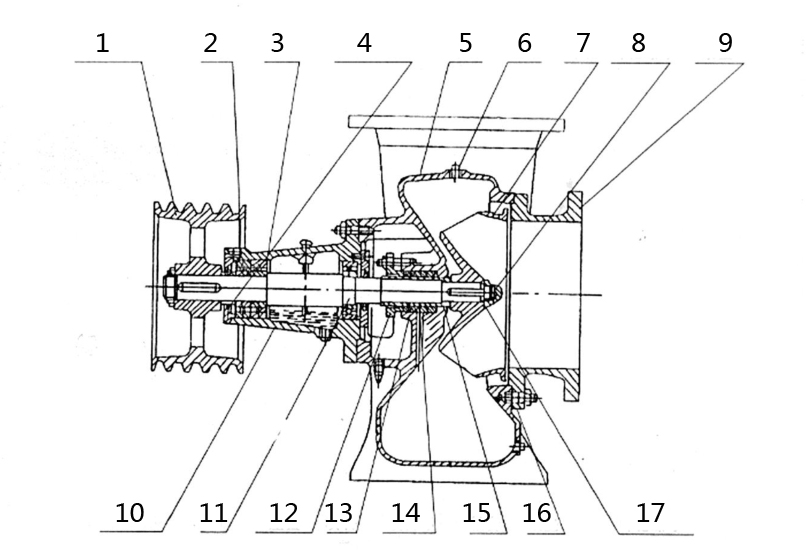

1. The HW type pump is mainly composed of main parts such as pump cover, impeller, pump body, pump shaft, shaft sleeve, and bearing body (diameter<350mm) or bearing frame (diameter>400mm) (Figure 1, Figure 2).

2. The pump cover is connected to the pump body and the inlet pipe respectively. There should be an appropriate gap between the pump cover plane and the impeller plane. A small gap can cause friction; Excessive clearance can cause a large amount of pressure water in the pump body to reflux, reducing the efficiency of the pump. The suitable gap for actual use is 0.3-0.7mm (pushing the pump shaft towards the inlet end of the pump), and the gap can be adjusted by increasing or decreasing the thickness of the paper pad.

3. The shaft seal device consists of packing, packing gland, packing ring, and packing box on the pump body (100HW, 150HW, and 200HW pumps do not have packing rings). Its function is to prevent air from being sucked into the pump and to prevent excessive water from flowing out along the shaft from the pump.

4. The shaft sleeve is used to protect the pump shaft. After wear and tear, it can be replaced in a timely manner.

5. The pump shaft is supported by a single row radial ball bearing. Bearings can be lubricated with lubricating oil - the amount of oil should be controlled between the markings of the oil benchmark; Lubricating grease can also be used for lubrication - it can be added when assembling the water pump. Supplement by disassembling and assembling the front and rear covers during use

6. The screw hole on the upper end of the pump body is used for adding water or connecting a vacuum pump for pumping water.

To expand the range of use of the pump and meet different user requirements, the outer diameter of the impeller can be cut or a different performance impeller can be used (indicated by the letter "A").

The accessories of the 8.150-300HW pump include inlet and outlet bends, flexible bends, bottom valves, and pulleys or couplings; The accessories of the 400-650HW pump include inlet and outlet bends, check valves, and pulleys or couplings. Available for users to choose from. 9. The bearing models and packing specifications of the HW pump are shown in Tables 1 and 2.Structural diagram

1. Belt pulley

2. Gear cover

3. Bearings

4. End cover of bearing body

5. Pump body

6. Screw plug

7. Impeller

8. Impeller nut

9. Pump cover

10. Bearing body

11. Axis

12. Packing gland

13. Filler

14. Packing ring

15. Shaft sleeve

16. Paper pad

17. Impeller nut

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.