Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

WQ submersible sewage pump

- 产品描述

-

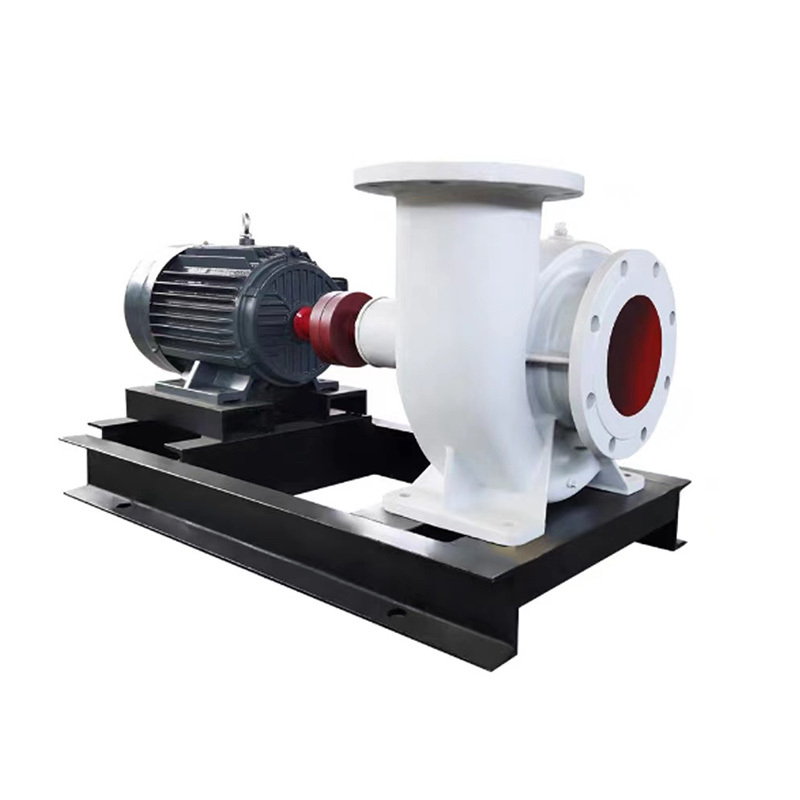

Product overview

WQ non-clogging submersible sewage pump is a new generation of pump products successfully developed on the basis of the introduction of foreign advanced technology, combined with the characteristics of domestic water pumps. It has the characteristics of significant energy saving effect, anti-winding, non-clogging, automatic installation and automatic control. In the discharge of solid particles and long fiber garbage, has a unique effect.

This series of pumps adopts unique impeller structure and new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller impeller, the pump impeller with single or double channel form, it is similar to the 1 section of the same size elbow, has a very good flow, with a reasonable worm chamber, making the pump has high efficiency, impeller by static and dynamic balance test, so that the pump in operation without vibration.

The hydraulic performance of the pump is advanced and mature, and the performance indicators of the product have been tested to meet the relevant standards. After the product is put on the market, it is welcomed and praised by the majority of users for its unique efficacy, reliable performance and stable quality.Product Features

1, The use of large channel anti-clogging hydraulic component design, greatly improving the dirt through capacity, can effectively through the pump diameter of 5 times the fiber material and the diameter of the pump diameter of about 50% of the solid particles.

2. Reasonable design, reasonable supporting motor, high efficiency and remarkable energy saving effect

3. The corrosion resistance and resistance of the pump shaft are greatly improved by chrome plating, and the service life of the whole pump is significantly improved. 4. The whole vulcanization technology of rubber sleeve is adopted at the connection between cable and motor, and its waterproof effect is long-lasting and reliable.

5. The mechanical seal adopts double series seal, the material is hard corrosion-resistant tungsten carbide, which is durable and wear-resistant, and can make the pump safe and continuous

Run more than 8000 hours.

6. The pump has compact structure, small size, convenient movement, easy installation, and no need to build a pump room. Dive into the water can work, greatly reducing the cost of the project.

7. Oil-water probe is arranged in the pump oil chamber. When the mechanical seal on the pump side is damaged, water enters the oil chamber, and the probe generates a signal to protect the pump.

8. It can be equipped with automatic safety protection control cabinet according to user's needs to monitor the leakage, leakage, overload and overtemperature of the pump to ensure the reliable and safe operation of the pump.9, double rail automatic coupling installation system, to the pump installation, maintenance has brought great convenience, people do not have to go in and out of the sump.

10. The float switch can automatically control the stop and start of the pump according to the required water level change, and no special person is required to take care of it.

11, in the use of lift range to ensure that the motor is not overloaded.

12, according to the use of the motor can be used in the water jacket type external circulation cooling system, can ensure the safe operation of the electric pump in the anhydrous (dry) state.

13. There are 2 installation methods: fixed automatic coupling installation and mobile free installation, which can meet different use occasions.Product application occasions

1, the factory commercial serious pollution wastewater discharge.

2. Drainage system of municipal wastewater treatment plant

3. Sewage drainage station in residential area.

4. Drainage station of civil air defense system.

5. Sewage discharge from hospitals and hotels.

6, municipal engineering, construction sites.

7, exploration, mining supporting machine.

8. Rural biogas digesters for farmland irrigation.

9. The water supply system of a water plant.

Pump usage conditions

1. The medium temperature does not exceed 60 ℃, the weight is 1.0-1.3kg/dm3, and the pH value is within the range of 5-9.

2. For pumps without internal self circulating cooling systems, the exposed liquid level of the motor part should not exceed 1/2.

3. In general, the pump must be used within the range of head to ensure that the motor is not overloaded. If it needs to be used within the full head range, it should be specified separately when ordering for the manufacturer to manufacture.

4. The current of the pump motor during operation shall not exceed the rated current of the motor.Model Meaning

100--Pump discharge nominal diameter (mm)

JY--Stir well

WQ--Submersible sewage pump

100--Rated flow rate (m3/h)

15--Rated head (m)

7.5--Rated power of equipped motor (KW)

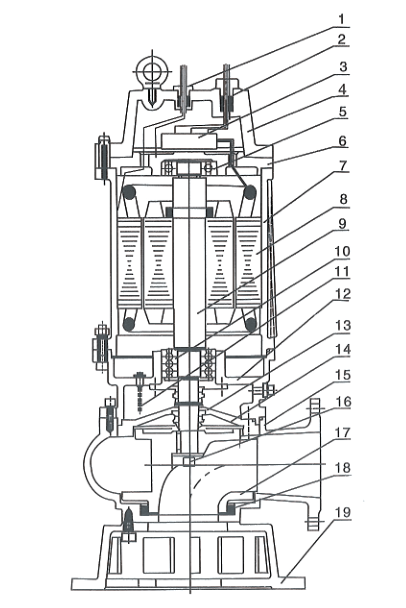

Structural description

The WQ type unobstructed submersible sewage pump consists of a motor and a pump, which are separated by an oil isolation chamber and mechanical seal components. It is an electromechanical integrated product, and the motor and pump share the same shaft (rotor). The entire length of the water pump is short and the structure is compact. Equipped with multiple protective devices to ensure safe and reliable operation of the pump. The main functions of its components are as follows:

Signal line 1: Equipped with a fully protected water pump control cabinet to provide all-round protection for the pump, including water leakage, phase failure, short circuit, overheating, motor overload, and other items. Motor stator 8: using B-class or F-class insulation,

Leakage probe 11: This component is installed in the oil chamber. When the mechanical seal is damaged and water enters the oil chamber, the probe can send a signal to the control system to implement the pump

Protection. Mechanical seal 13: Adopting dual channel series sealing, using a new type of hard and corrosion-resistant tungsten carbide material, which has the characteristics of reliable sealing, durability, and long service life. Impeller 17: The impeller adopts a single or double channel structure, which has strong passing capacity and can pass through large materials and fiber waste, reducing the risk of blockage and entanglement.

Pump body 15: matched with impeller, making the pump highly efficient,

Sealing ring 18: installed at the mouth ring of the pump body. When the impeller is damaged at the mouth ring due to operation, the sealing ring can be replaced to ensure that the pump operates at the best efficiency

1. Signal line

2. Motor wiring

3. Junction box

4. Motor cover

5. Bearing shaft

6. Upper shaft seat

7. Motor casing

8. Stator

9. Shaft (rotor)

10. Bearings

11. Oil water probe

12. Oil chamber

13. Mechanical seal

14. Rear cover plate

15. Pump body

16. Impeller bolts

17. Impeller

18. Sealing ring

19. Chassis

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.