Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

YW sewage pump

- 产品描述

-

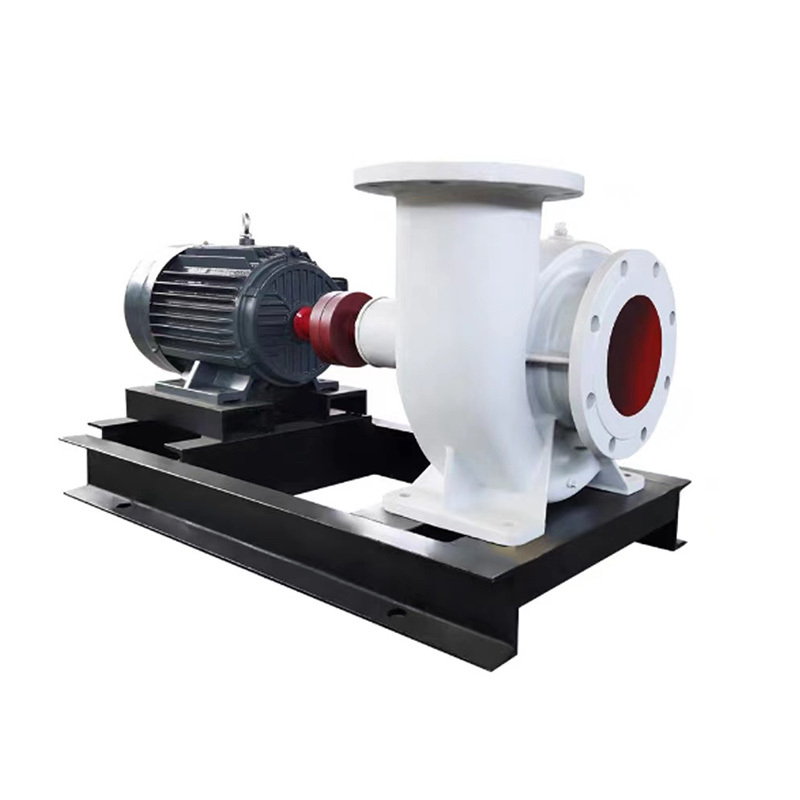

Overview

The YZ type submersible slurry pump is a vertical single-stage single suction cantilever centrifugal pump structure. The impeller is a semi open impeller, and there are stirring blades at the extension of the impeller suction edge.

The two series pumps are mainly used in industries such as environmental protection, municipal engineering, thermal power plants, gas coking plants, refineries, steel mills, mining, papermaking, cement plants, food plants, printing and dyeing to extract concentrated liquids, heavy oils, oil residues, polluted liquids, mud, mortar, quicksand, and flowing sludge from urban sewage channels, as well as fluids containing mud, sand, slag, and corrosive liquids. YW type can also be used as a large and medium-sized biogas digester for extracting various types of human and animal manure and sewage, and is used for discharging during biogas engineering. YZ type can also transport high-temperature (480 ℃) kerosene, crude oil, asphalt, oil residue and other working conditions.

Model Meaning

80YZ80-20A

YZ--submersible slurry pump

80-- Pump outlet diameter (mm)

80-- Design point flow rate of pump (m 3/h)

20-- Design point head of pump (m)

A -- indicates that the impeller has been cut for the first timeStructural description

1. The YW type pump is a single-stage single suction centrifugal pump, which is connected to the hydraulic components, bearing body, and support disk of the pump through a connecting pipe. The liquid is discharged from the outlet pipe component, and the impeller is a semi open impeller. There are stirring blades at the inlet extension of the impeller blades, which can transport media containing particles. The maximum submerged depth of the pump is 8m. When the submerged length exceeds 1.5m, a shaft connection structure should be adopted, and rolling bearings (lubricated with grease) should be installed near the shaft connection, connected by a coupling sleeve. The rolling bearings at the bottom of the pump are isolated from the liquid level by mechanical seals and do not come into contact with the liquid. The pump bearings have sufficient rigidity to ensure smooth operation of the pump. If operating in deep wells, a suction pipe can be added (as specified in the contract).

2. The YZ type pump is a single-stage, single suction cantilever structure, connected to the hydraulic components of the pump through bearing seats, support seats, and connecting pipes. The liquid is discharged through the outlet pipe components. The impeller of the pump is a semi open impeller, and there are stirring blades at the inlet extension of the impeller blades. The main feature of this pump is that the pump shaft in the underwater part has sufficient rigidity, and there are no bearings or shaft seals between the impeller and pump casing. It can transport media containing high concentrations of solid particles. The length of the liquid pumped into the pump is between 800-2000, and if necessary, a suction pipe can be equipped. The shaft seal adopts a submersible pump inserted into the liquid for operation, without a shaft seal. The transmission is installed on the motor support and support seat by a vertical motor, and connected to the pump with a coupling.Structural diagram

1. Front cover

2. Impeller

3. Pump body

4. Pump cover

5. Machine sealed room

6. Shaft sleeve

7. Mechanical seal

8. Bearing body

9. Axis

10. Bearing end cap

11. Connecting pipe

12. Joint shaft sleeve

13. Motor seat

14. Coupling

15. Electric motor

16. Supporting disk

17. Water outlet pipe

18. Bend

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.