Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

Submersible slurry pump

- 产品描述

-

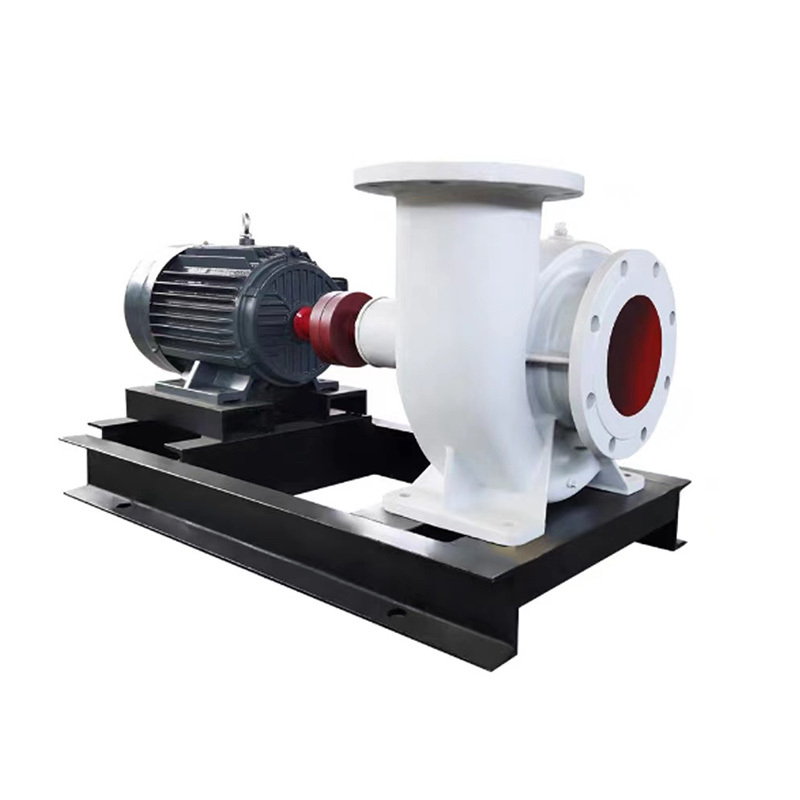

Overview

The ZJQ submersible slurry pump has been comprehensively optimized and innovatively designed in terms of hydraulic model, sealing technology, mechanical structure, protection and control. This product has a simple structure, easy installation, safe and reliable use, and long service life. Pump submerged underwater without the need

Constructing complex ground pump rooms and fixed installations, with no noise or vibration, making the site cleaner.Main purpose

This product is suitable for conveying slurry containing abrasive particles such as sand and gravel, coal slag, and tailings. It is mainly used in industries such as metallurgy, mining, power, chemical, environmental protection, river dredging, sand extraction, and municipal engineering. This product is easy to install and move, with high slag extraction efficiency, and can operate safely for a long time under harsh working conditions. It is a replacement for traditional vertical submersible pumps and submersible sewage pumps

Think about the product.Conditions of Use

1. Power supply 380V, three-phase, 50HZ (customized voltage and frequency according to requirements);

2. The temperature of the medium generally does not exceed 60 ℃, the pH value is 4-10, and the density of the medium is ≤ 1300kg/m ³;

3. Suitable for media with strong abrasive solid particles and mildly corrosive sewage slurry;

4. The diameter of solid matter in the medium shall not exceed 80% of the minimum flow channel size of the pump.

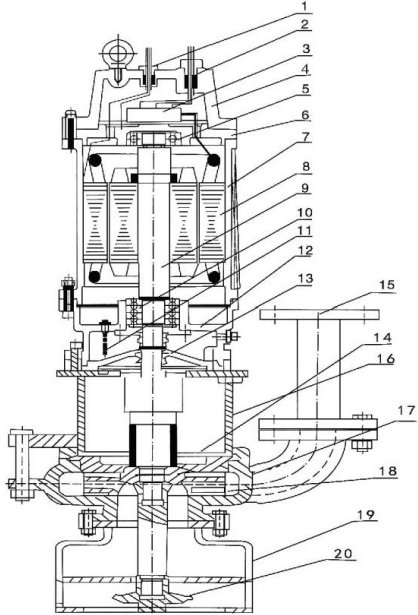

Product Structure Description

1. Signal line

2. Motor wiring

3. Junction box

4. Motor cover

5. Bearings

6. Upper shaft seat

7. Motor casing

8. Stator

9. Shaft (rotor)

10. Bearings

11. Oil water probe

12. Oil chamber

13. Mechanical seal

14. Protective board

15. Water outlet pipe

16. Bracket

17. Pump body

18. Impeller

19. Base filter screen

20. Mixing wheelStructural description

1. Pump body impeller

Based on actual testing, carefully select and match the pump body and impeller. The impeller of the pump body is made of high chromium wear-resistant and corrosion-resistant materials

Material, good overcurrent performance, high efficiency, flat power curve, not easily overloaded, precise impeller balance, low vibration operation

Smooth transition.

2. Mixing wheel

The mixing wheel is located at the bottom of the pump, which can stir the sediment settled at the bottom of the water into turbulence and extract it, collecting water and stirring

Mixing, blowing sand, and extracting sand in one, with high sand absorption efficiency and more thorough dredging.

3. Motor

Specially designed submersible motor, IPX8 protection, F-class insulation allows for temperature rise. Under normal temperature rise conditions, the motor

Long insulation life, good diving cooling effect, low actual temperature rise, and longer insulation life of the motor.

4. Motor cooling

The motor generates heat through the casing, and as long as the medium submerges the motor stator casing, it can operate reliably and safely

The more, the more effective the use of motor cooling.

5. Shaft seal

The motor shaft seal adopts two independent series connected mechanical seals, forming two reliable sealing lines. The first passage is in the medium inside the pump, and the sealing surface is pressed tighter with the increase of medium pressure, effectively preventing water from entering the oil chamber. The second passage is in the oil chamber, preventing oil from entering the motor. If the first passage fails (its working conditions are worse than the second passage), the second passage can still prevent water from entering the motor

Stop oil and water from entering the motor. The corrugated tube type machine seal combined with innovative structural cavity greatly improves the reliability of the shaft seal

Under normal usage, the fault free running time exceeds 8000 hours.

6. Oil chamber

The oil chamber is a barrier that prevents the medium from entering the motor from the pump shaft, preventing the medium from penetrating into the electrodes. If the first seal leaks, the buffer medium in the oil chamber cannot directly enter the motor. Simultaneously lubricate and cool the friction surfaces of two independent machine seals

To make the sealing work more reliable, it can also take away the heat generated by the lower bearings and some of the heat generated by the motor.

7. Bearing

The lower double row angular contact bearing has strong load-bearing capacity and, together with the upper deep groove bearing, forms a reliable support for the motor water pump shaft. It has a large bearing margin for the radial, axial, and other forces generated during the operation of the sewage pump, ensuring the stability of the unit

Operation and long lifespan

8. Cable and its sealing

1) The cable is a heavy-duty rubber sheathed flexible cable that is resistant to sewage. The cross-sectional area of the cable core is designed for long-term reliable operation at an ambient temperature of 40 ℃ and full load power of the motor. If the sewage pump is working, the motor will operate at non full load power or below 40 ℃ in the environment

Okay, the service life will be longer.

2) There is a sealed compression between the cable rubber sleeve and the motor cover to prevent the medium from seeping into the interface between the cable and the motor cover

Internal cavity of the machine.

3) There is rubber vulcanization between the cable sheath and the core, which can effectively prevent the medium from coming out of the cable sheath once the rubber sheath is scratched

Enter the motor internally.

9. Motor casing

The motor housing is composed of the casing, upper end cover, and pressure cover, and reliable static seals are provided at the connection and fitting points of each component

All have undergone strict hydrostatic testing to ensure that there is no leakage and there is no risk of failure.

10. Internal safety protection of the pump (activated through a dedicated electrical control cabinet)

1) Oil water probe: installed in the oil chamber to detect the leakage of the first mechanical seal (in the medium). When the medium leaks

When reaching a certain proportion in the oil chamber, an alarm signal will be issued.

2) Float switch: installed in the motor chamber to detect the leakage of the second seal, when oil (oil-water mixture) enters

The motor and float switch will send an alarm signal and stop the pump.

3) Thermistor: Installed inside the stator winding of the motor, if the motor is overloaded for a long time, the temperature of the motor winding (or other factors) will be affected

When the heating of the motor winding reaches a certain value, an alarm signal is issued and the pump is stopped.11. External control system

The supporting dedicated electrical control cabinet can process various signals inside the pump, achieving functions such as control, protection, sound and light alarm, etc

Capable of various automation controls with single and multiple pumps.

When users bring their own electrical control cabinets, they should contact our company's electrical control cabinet professional team to guide users in installing them inside the cabinets

Install a protective controller.

12. Optional equipment

Forced cooling system. Install a metal sleeve on the motor casing to introduce cooling water circulation and achieve forced cooling. 13. Performance curve and main parameters

The actual part of the curve on the performance curve graph represents the recommended range of use for the pump. The shaft power of the pump increases with the increase of flow rate. If the flow rate of the pump exceeds the rated flow limit, the shaft power will exceed the rated power of the motor. When the medium temperature is high or the motor cannot be sufficiently cooled, the motor cannot work for a long time; If the flow rate is less than the rated flow limit, the shaft power of the pump is much lower than the rated power of the motor, and the efficiency of the unit is very low. It is not advisable to use a pump under such working conditions

Economically.

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

Keywords:

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.