Contact us

E-mail: sales@huitong-pump.com

Phone: +86-13730207380

WhatsApp: +8613730207380

Nanyang Industrial Zone, Anguo City, Baoding, Hebei, China

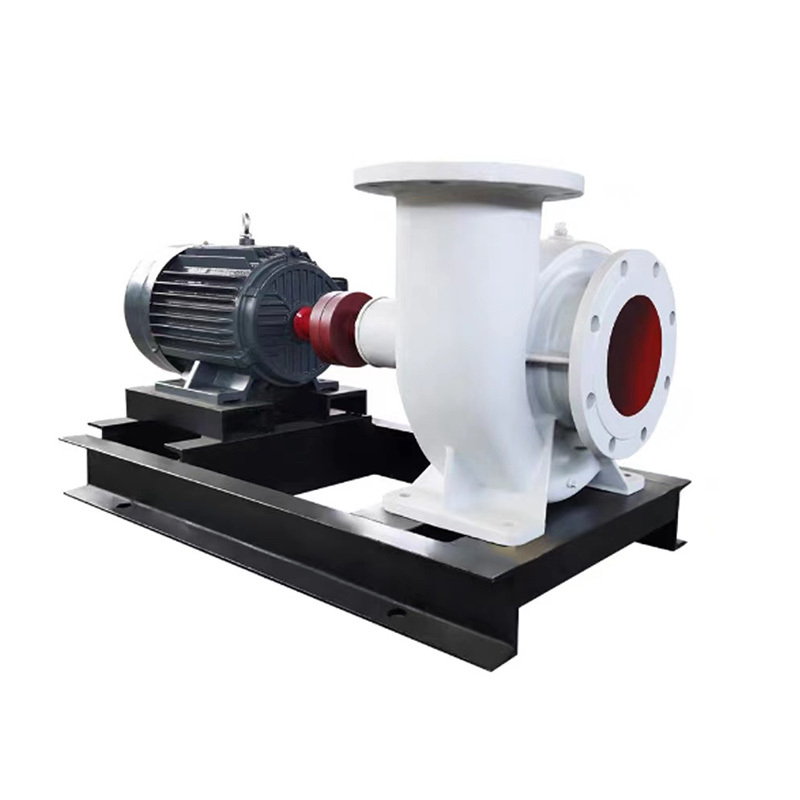

ISG pipeline pump

- 产品描述

-

Use

1. HTG and HTW vertical pipelines and horizontal direct-connected centrifugal pumps are used for conveying clear water and other liquids with physical and chemical properties similar to clear water. They are suitable for industrial and urban water supply and drainage, pressurized water supply for high-rise buildings, garden sprinkler irrigation, fire fighting and pressurization, long-distance transportation, HVAC cycle, bathroom and other cold and warm water circulation pressurization and equipment matching, with a service temperature of T<80 ℃.

2. IRG(GRG) IRW vertical pipeline and horizontal direct-connected hot water (high temperature) circulating pump are widely used in high-temperature hot water pressurized circulating transportation of boilers such as energy, metallurgy, chemical industry, textile, papermaking, hotels and restaurants, and circulating pumps for urban heating systems. IRG operating temperature T<120 ℃,GRG operating temperature T<240 ℃.

3, IHG, IHW type vertical pipeline, horizontal direct chemical pump, for the transport of solid particles, corrosive, viscosity similar to water liquid, suitable for petroleum, chemical, metallurgy, electric power, paper, food and pharmaceutical and synthetic fiber and other departments, the use of temperature is -20 ℃ ~ 120 ℃.

4. YG and YW vertical pipelines and horizontal direct-link oil pumps are used to transport gasoline, kerosene, diesel and other petroleum products. The temperature of the transported medium is -20 ℃ ~ 120 ℃.Model meaning

HTG--Pump Category(HTG, HTWV single-stage single-suction pipeline direct centrifugal pump/IRG, IRWV single-stage single-suction hot water pipeline direct centrifugal pump/GRG, GRWV single stage single suction high temperature pipeline direct centrifugal pump/IHG, IHWV single stage single suction direct connection chemical pump/YG, YWV single-stage single-suction pipeline direct centrifugal oil pump)

50--Nominal diameter of pump inlet and outlet (mm)

160--Nominal outer diameter of impeller (mm)

(1)--Traffic classification

A(B)--Impeller first cut

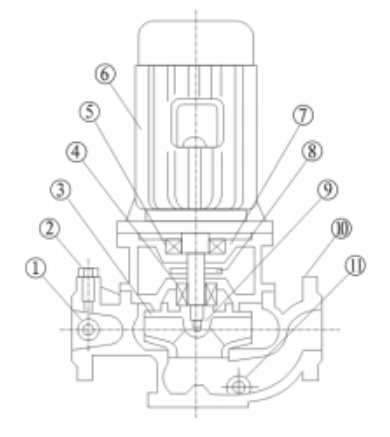

Structure diagram and description

1. Water intake plug

2. Exhaust valve

3. Impeller

4. Mechanical seal

5. Bearing

6. Motor

7. Conjoined seat

8. Water retaining ring

9. Impeller nut 10. Pump body

11. Water release valve

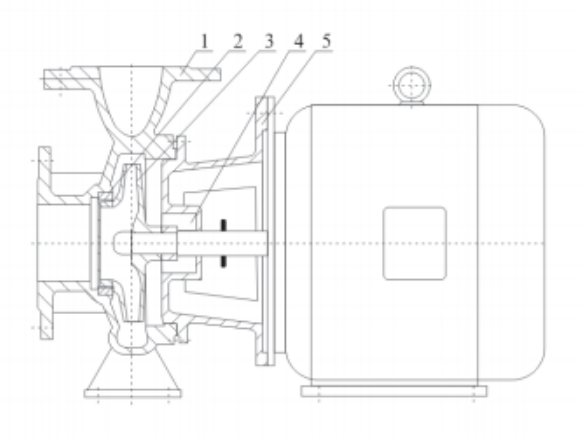

1. Pump body

2. Seal ring

3. Impeller

4. Mechanical seal

5. Pump coverY series motor: directly connected with water pump to transmit motion

Force.

Bearing: coaxial with the motor, the motor lengthened shaft to ensure the concentricity of the shaft, so that the pump runs smoothly without noise and vibration, the use of chrome plating treatment, enhance the service life.

Water retaining ring: prevent water from entering the motor due to water leakage from the seal.

The coupling seat: cleverly designed, both beautiful and lowered the center of gravity of the pump and the cantilever of the shaft is enhanced. Operation stability life of the pump.

Mechanical seal: made of stainless steel, tungsten carbide, fluorine rubber and other materials. Balanced high temperature, high pressure mechanical seal, long operating life, no leakage, no wear on the shaft, no scale, to ensure the cleanliness of the working environment.

Pressure plug: install pressure gauge and vacuum pressure gauge to monitor the normal and efficient operation of the pump.

Pump body: The pressure chamber and suction chamber are designed with excellent hydraulic models, which are both beautiful and efficient. They are equipped with mounting feet for easy installation and stable operation.

Dump valve: to ensure the normal maintenance of the pump.

Exhaust valve: the pump can drain the air in the pump to ensure the normal start of the pump.

Impeller: the use of excellent hydraulic model design, with high efficiency, good reliability and other characteristics.

Bearings: to ensure the accuracy of the shaft to improve the reliability of mechanical seals.

FAQ

Q

Can you provide product repair and maintenance services?

A

Q

Product problems, how to get after-sales support?

A

Q

What is the mode of transport of goods?

A

Q

What are the payment methods?

A

Q

How to purchase your products?

A

Q

How to determine the price of customized products?

A

No matter how complex your needs are, just tell the specific parameters, application scenarios and performance goals, and our technical team will provide you with a one-stop service from solution design to delivery to ensure that the product meets your needs by 100! Contact us today to start a customized tour.

FAQ

Q

Can you provide product repair and maintenance services?

A

Of course. We not only provide after-sales service, but also provide you with professional maintenance advice and training. Our technicians can carry out regular inspection and maintenance for your equipment, find and solve potential problems in time, extend the service life of equipment, and reduce your operating costs.

Q

Product problems, how to get after-sales support?

A

If you encounter problems in the process of using our products, you can contact our after-sales team at any time. You can feedback your questions through the after-sales consultation channel on the website, and we will respond within [specific time]. For common problems, we will guide you to solve them by phone or email; if you need on-site service, we will arrange professional and technical personnel to go to your location as soon as possible.

Q

What is the mode of transport of goods?

A

We cooperate with a number of professional international freight forwarding companies, and can choose the appropriate mode of transportation according to your requirements, including sea, air, land, etc. At the time of order confirmation, we will recommend you the most cost-effective transportation plan according to the weight, volume, delivery time and other factors, and be responsible for the safe delivery of the goods to the place you specify.

Q

What are the payment methods?

A

We accept a variety of international payment methods, such as T/T (wire transfer), L/C (letter of credit) and so on. The specific payment method can be determined through negotiation with us according to your needs and orders.

Q

How to purchase your products?

A

You can leave your purchase requirements and contact information through the online consultation function of our foreign trade website; you can also send mail directly to our business mailbox, or call the contact number published on the website. Our business team will contact you as soon as possible after receiving the information to communicate the specific order details, including product specifications, quantity, price, delivery date, etc., and place the order after confirmation.

Q

How to determine the price of customized products?

A

The price of customized products mainly depends on the specific requirements of customization, including material selection, process complexity, accessory selection, etc. We will conduct detailed cost accounting according to your customized needs and provide you with a reasonable and competitive quotation.